|

||

|

|||||||||||||||

|

#21

|

||||

|

||||

|

i did read the post above but can't see how a servo be can slower when stood up then to been layed down!

or was he just saying all low profiled servo's are slow |

|

#22

|

||||

|

||||

|

apprently digital servos use more battery than analog?

|

|

#23

|

||||

|

||||

|

i have a futaba 9550 low profile servo in mine, and whilst it isn't as fast as my KO servos it's not slow!

I also have the servo arm facing into the car for steering, to avoid hitting the bodyshell... |

|

#24

|

||||

|

||||

|

I've got a futaba 9551 in mine and it works fine, plenty of speed and torque. Its also clear of the bodyshell.

Even if digital servos use more power than analogue ones I shouldn't worry batteries have so much energy in them it doesn't make any difference.

__________________

Lets Off Road! |

|

#25

|

||||

|

||||

|

I had a (s)low profile in my 2wd and it sucked... was fine in the 4wd though.

__________________

www.rc-offroad.be Never argue with a stupid man. He will drag you down to his level and beat you because of his experience. |

|

#26

|

||||

|

||||

|

Quote:

Servo + receiver parallel (ko low profile + spectrum sr3100 fit nicely) and as close as possible to the motor and my speedo (mamba) upfront. I think i have seen this layout somewhere in here in the past ( i think was niggs car or kevlee) and i believe it should be perfect.

__________________

AGAMA USA - VP PRO USA - BULLIT ENGINES |

|

#27

|

||||

|

||||

|

Here are pictures of Kev's car from Jan. and March of this year. Apparently he has tried the stand up and lay down servo versions. I would think the laydown version would be better.

Maybe he can pitch in and off advantages and disadvantages of both. |

|

#28

|

||||

|

||||

|

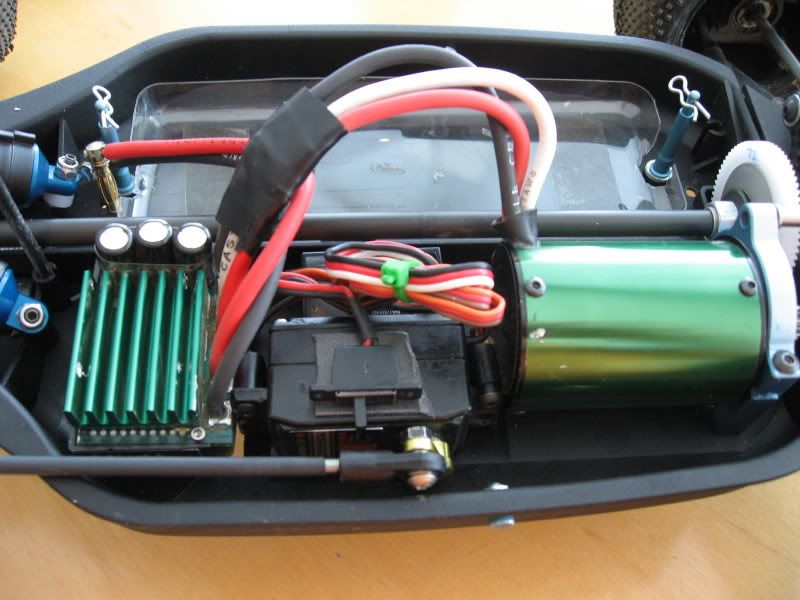

Well here is my lipo stick conversion with the new orange steering parts/plastic chassis.....decided to go with lay down servo option as now there is plenty of space plus i have the alum servo blue posts spare so that i can make the short pushrod mode. Also need to figure out how to get rid of all this "spaghetti" wire i have created ....

__________________

AGAMA USA - VP PRO USA - BULLIT ENGINES |

|

#29

|

||||

|

||||

|

nice fit, Panic

but lucky for you, you had a low profile servo and a small footprint receiver  I guess it will always be difficult to install "normal size" electronics in a Pred. Anyway: good job! edit: dude, do not forget to mount the very important motor-screw that attaches the motor mount to the Rear small suspension plate, via the motor mount brace. On your pictures it seems to be missing. |

|

#30

|

||||

|

||||

|

Quote:

__________________

AGAMA USA - VP PRO USA - BULLIT ENGINES |

|

#31

|

||||

|

||||

|

good spot ludo.

that is the most imprtant screw in the whole car. evebn known as the jesus screw lol that is the most imprtant screw in the whole car. evebn known as the jesus screw lol

__________________

Nathan Ralls HPI, Custom Blitz, www.piraterc.com mr-o foams woop woop racing officialy keeping team toe out inline

|

|

#32

|

||||

|

||||

|

lol, "Jesus Screw", the best name "evah" for a part of a rc-car. I'll remember that one

@ Panic, actually, (excuse me for mentioning this) I DO see a flaw in your layout. It is not possible for you to dismount the motor without dismounting the servo. I won't be too easy either (if possible?!) to change a pinion this way. |

|

#33

|

|||

|

|||

|

could he take the whole motor mount out, then the motor? though its still alot of work.

im getting an x10 soon and i waswondering if a servo just bigger than a normal servo will fit? (longer, not wider) thanks chris |

|

#34

|

||||

|

||||

|

Quote:

What kind of servo is that ?

__________________

AGAMA USA - VP PRO USA - BULLIT ENGINES |

|

#35

|

||||

|

||||

|

Quote:

But in general i dont touch the motor too often neither the pinion...so no harm for me.

__________________

AGAMA USA - VP PRO USA - BULLIT ENGINES |

|

#36

|

|||

|

|||

|

a strange one, lol

ansman metle gear 6kg servo, nothing expensive and fancy, but its reasonable quick and metle geard. speed: 0.15 sec size: 40.5 x 20 x 41.2 mm weight 43g |

|

#37

|

||||

|

||||

|

* UPDATE *

So today was another club race at the same track here in Vancouver CANADA.My first time though with the lipo stick conversion, new orange steering arms , plastic chassis , proline wing all the way forward with half gurney - ....and all i can say is WOW!!!!. Completely different car. More steering, more pivot into corners and jump was most of the times level....  i like it !!! i like it !!!Ofcourse i once again had a bad start. I was practicing before the qualifiers and i broke the other crank pivot (and that was it - no other issues). I guess those new beefier pivots are NOT  so beefy (and now i ended up using the old ones again). Need to find out how to make them stronger any ideas? Or any other solution? so beefy (and now i ended up using the old ones again). Need to find out how to make them stronger any ideas? Or any other solution?

__________________

AGAMA USA - VP PRO USA - BULLIT ENGINES |

|

#38

|

||||

|

||||

|

was the pivot that you broke a new solid one as if so it is the first that i have heard of breaking. if this is the case can you pm me with some pics please

__________________

Nathan Ralls HPI, Custom Blitz, www.piraterc.com mr-o foams woop woop racing officialy keeping team toe out inline

|

|

#39

|

|||

|

|||

|

to be honest i think the only way to get them stronger is to make them out of titanium.. but i dont think that is needed..

you might have had to much stress on it.. when you compress the front suspension down does the chassis touch the table surface? also is there any more up travel from this position?

__________________

RC US Imports - Sworkz USA- Maclan Racing- Bellgate Distributors. |

|

#40

|

|||

|

|||

|

couldnt you use softer springs? so it will touch down flat instead of having stress on only 4 points?

also if you make something too strong it will only put more stress on something else...so if you use titanium, all you do is transfer the stress. thats why people dont use aluminum... |

|

| Thread Tools | |

| Display Modes | |

|

|