|

||

|

|||||||||||||||

|

#21

|

||||

|

||||

|

The standard belt I four usually sits to one side but under load would track central.

If you had of said before I would of put you a couple of the carbon pulley fences for the overdrive pulley I use in with your bumper pal.

__________________

My feedback feel free to add anything  http://www.oople.com/forums/showthre...863#post861863 |

|

#22

|

|||

|

|||

|

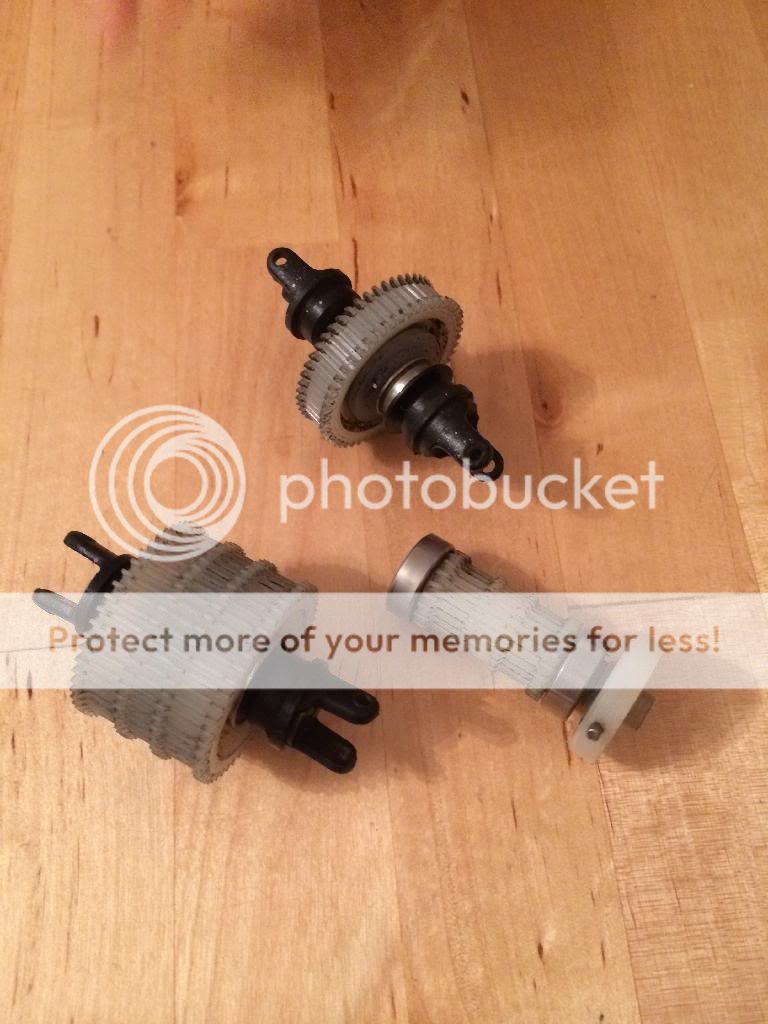

I took the front diff apart, and the centre hub of the diff is chewed up, or looks like it was cut down. It has the number T203 on it instead of the stock T173

|

|

#23

|

|||

|

|||

|

Pulley fences would definitely help.

I have a good reason to wait for the MMS diff now though. The diff pulley wobbles around because of the worn center supports. I have a good reason to wait for the MMS diff now though. The diff pulley wobbles around because of the worn center supports.

|

|

#24

|

|||

|

|||

|

I've drawn up a diff pulley in CAD now. I could CNC-mill one out of delrin, with fences, if I wasn't so lazy.

|

|

#25

|

||||

|

||||

|

I prefer this trinity diff over the mms one personally but I couldn't use the mms one with the 6 belt

__________________

My feedback feel free to add anything  http://www.oople.com/forums/showthre...863#post861863 |

|

#26

|

||||

|

||||

|

I thought the Trinity and MMS diffs were the same?

Perhaps my memory is going! My rear diff definitely looks like yours in the picture though Peakey. Perhaps someone can confirm?

__________________

|

|

#27

|

|||

|

|||

|

Temporary solution. I put the diff pulley in my lathe and made two slots around and then glued thin O-rings int he slots to act as fences.

|

|

#28

|

||||

|

||||

|

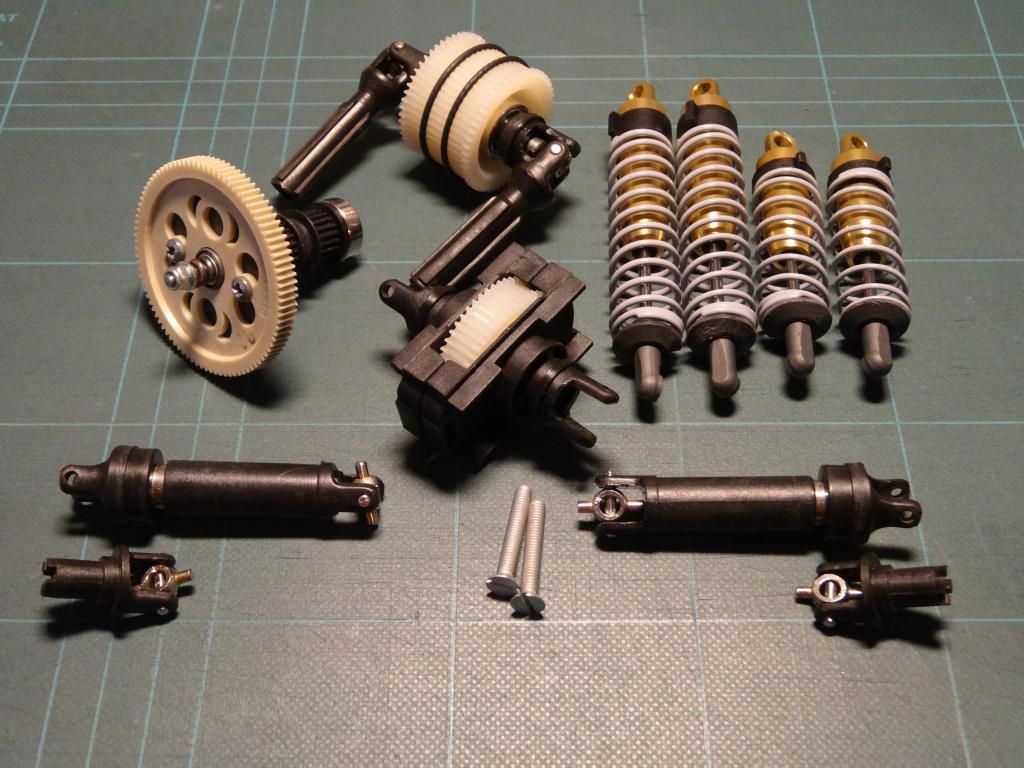

The trinity one had no fences cut in to the drum where as the MMS one did here's a full set of MMS pulleys

Nice job on the pulley

__________________

My feedback feel free to add anything  http://www.oople.com/forums/showthre...863#post861863 |

|

#29

|

|||

|

|||

|

I also made a brass center section for the pulley so it won't wobble. Didn't take a picture. It spins true now, and the belt stays where it should. It doesn't skip and it's not as tight as before. It's all good now.

|

|

#30

|

|||

|

|||

|

Ready for some testing tomorrow. Just needs a bumper, but it runs. Maybe I'll head to a track on saturday. Haven't driven on a track in 22-23 years.

|

|

#31

|

||||

|

||||

|

Found my original instructions from when I purchased my MMS Diff and it has no machined in central fences.

Perhaps they changed the design as some point? |

|

#32

|

||||

|

||||

|

My MMS rear diff has machined grooves into which O'rings are seated, just as tahustvedt has done!

Justin - I can't believe you are running your ProCat with a 5.5bl!!  - I feel that mine is just on the edge of what is acceptable with a mild (Old Hacker motor) 6.5bl... which if I'm honest is quite quick enough! - I feel that mine is just on the edge of what is acceptable with a mild (Old Hacker motor) 6.5bl... which if I'm honest is quite quick enough! My ProCat is running the slipper/layshaft assembly & rear Pro-diff from a comp-spec BossCat - also the MMS front diff pulley - so far (touching wood) I have not experienced any belt slip in the four-five meetings at which its been run, although I would say that the main/long belt is probably set tighter than I would if I was running it with a brushed motor.

__________________

TeamC TM2 (V1) Xray T4 15' (I finally conformed!) Associated R5.1 1/12th Pan Car (Occasional Racer) + too many vintage racers to list! |

|

#33

|

||||

|

||||

|

Hi Dan,

That's what my MMS diff looks like, it has the o rings to separate the three belts.

__________________

|

|

#34

|

||||

|

||||

|

Quote:

that's how I roll that's how I roll  tbh I thought I needed a little more punch so I'm gonna adjust the Esc and see how it performs. tbh I thought I needed a little more punch so I'm gonna adjust the Esc and see how it performs.Best thing about it nothing could out run me on the strait  but on the in field I was having "roll" issues which should be sorted now. but on the in field I was having "roll" issues which should be sorted now.As for the diffs mine could be the later or earlier one?

__________________

My feedback feel free to add anything  http://www.oople.com/forums/showthre...863#post861863 Last edited by Peakey; 10-10-2014 at 03:10 PM. |

|

#35

|

|||

|

|||

|

Hey. MMS copied me.

I probably got the idea from a picture of the MMS diff somewhere. I probably got the idea from a picture of the MMS diff somewhere.I was going to test today but it was getting dark when I got home from work. I live at 69░N and the days are starting to get very short. |

|

#36

|

|||

|

|||

|

I have a 5.5 turn motor and it's way too fast. It's ridiculous. I'm going to change to a 13.5 turn motor I have as I won't be racing it. I let a girlfriend of mine try it today and turned down the throttle to 35%. That seemed to calm it down to sensible speeds.

|

|

#37

|

|||

|

|||

|

Guess what. I made a new diff from acetal, and it works great! I made it with fences on both sides. I miscalculated slightly when I programmed the width of the belt track, so it's just 5 mm when I was going for 6. Doesn't matter as my belt is just 4,5 mm.

It looks messy around the edges in the photo but it's just some flash and dust from the milling. After the photo I turned it around and milled the other side, and then chamfered the edges in my lathe. Changes I woud make is to reduce the diameter of the fences by 0,5 mm and add a chamfering toolpath so I don't have to do it in the lathe. The stock pulley actually meshes poorly with the belt as it's 0.5 mm too small in diameter. This one is a better fit. Last edited by tahustvedt; 12-10-2014 at 10:01 PM. |

|

#38

|

|||

|

|||

|

CNC video: http://youtu.be/EJFVhXN8NWo

|

|

#39

|

||||

|

||||

|

I think we might see a new line of diffs coming out of Norway soon

__________________

My feedback feel free to add anything  http://www.oople.com/forums/showthre...863#post861863 |

|

#40

|

|||

|

|||

|

If I make some extra diffs I'll be sure to post about it here.

|

|

| Thread Tools | |

| Display Modes | |

|

|