|

||

|

|||||||||||||||

|

#21

|

||||

|

||||

|

Thats what I did (well my father in law) and it works fine with a bit of shimming and extra bearings.

|

|

#22

|

|||

|

|||

|

Drilling would work I'm sure, except I don't have access to a drill press.

What I have discovered however is that you can still pick up the entire BK2 CVD assembly, part number LOSA9984. Just do a search on EBay. X6 is now on its way! Cheers, Scott |

|

#23

|

||||

|

||||

|

Hi,

Just purchased some of the longer CVD axles for my new x6 sq, which are conveniently bagged as X-factory parts these days, and having got them and tried to fit them I've now realised that I should have also picked up axle spacers to make them work in the car...a point which I missed when reading the many posts about these...my own fault for not reading things properly I guess. Just wondered if you'd (hoping one the X-factory guys will read this) considered sourcing some suitable spacers and shipping them with the axles as a complete kit that works out of the bag? Just a thought...could be a nice touch to finish off the hop-up

__________________

AKA: Andy Nancollis 1/10th drives: Yokomo BMax2MR & BMax4 1/16th drive: Carisma GTB Racing in South West: http://www.mendiprcraceway.co.uk/ Racing in Wales: www.caldicotrcracers.co.uk Kept running by: Yokomo via MB Models & www.tracksidespares.co.uk Shells by Square Crabs |

|

#24

|

||||

|

||||

|

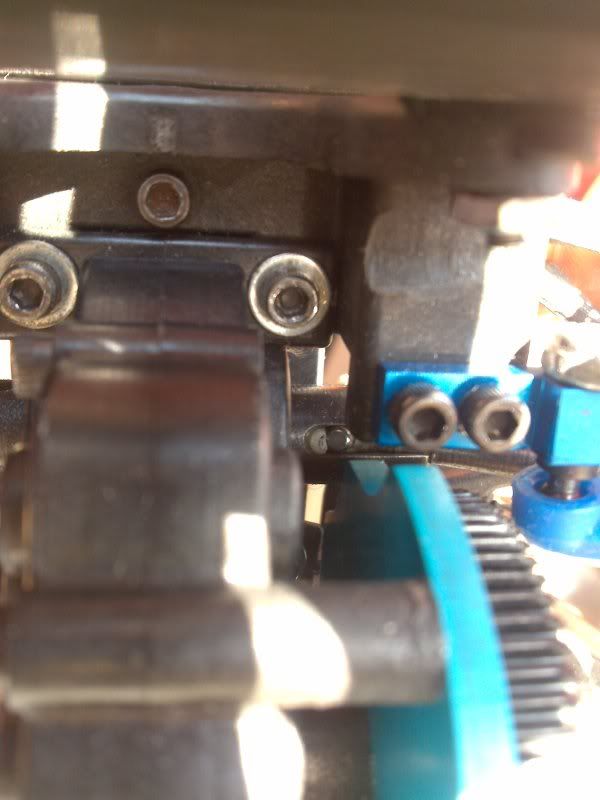

I've got a question... I have BK2 rear axles and standard AE shafts, and have spaced them so that they axle goes further inside the outdrive, but what I've noticed is that on the Spur gear side where the white diff nut is, upon full compression of the shock the end of the driveshaft hits the white diff nut before the shock hits full travel.

Is this a problem that others have experienced... if not, what am I doing wrong??? I have tried putting a 2mm washer on the shaft on the outside to try and restrict full travel but I need more if I want to eliminate it fouling on the diff screw. Just doesn't seem right but nobody has been able to explain a solution. Below is a pic so that you can see where its fouling:  Thanks, Jon |

|

#25

|

||||

|

||||

|

Good pic, Jon. Shows the problem clearly and exactly. I'll let the Boyz answer.

On the spacer thing, most people use the Losi 3016 axle spacers. We don't include them in the package because we would buy them from Horizon at the same price as any hobby store pays, then add a small profit for us and sell them to hobby stores. Result = you would pay more. If your LHS does not have them, we do. |

|

#26

|

||||

|

||||

|

Anyone got a picture of these axle spacers?

|

|

#27

|

|||

|

|||

|

I limit the outer part of the shock so it won't hit the plastic part, think it is about 3mm if I remember correctly.

|

|

#28

|

||||

|

||||

|

when you say that you limit the outer by 3mm do you mean that you put a 3mm washer on the exterior part of the shock shaft?!

Thanks, Jon |

|

#29

|

|||

|

|||

|

Yep.

|

|

#30

|

||||

|

||||

|

Another option IF you cant find the axles required its to insert a couple of mm of spacers inside the shock to limit the droop.... thus forcing the drivshaft inside the outdrive a little, not a permenant solution really, but might help stop the "bone" falling out during larger jumps etc...Sacrificing the droop is only really an option on smoother surfaces, not bumpy.

__________________

schumacher procat x Two, one bosscat, one rc10 gold pan, two optima mids, one cougar/club10 |

|

#31

|

||||

|

||||

|

Quote:

I'm gonna give the 3mm spacers a go like Ellis does but i dont like it... the atomic carbon s2 has standard ae axles and that car generates more droop without any problem of driveshafts popping out or fouling on the diff screw... surely X factory could have designed something better that worked??? This really shouldn't be a problem that we're still having - fair enough the x6 had teathing problems but bringing out the x6 squared with the same unsolved problem seems daft to me! Just my opinion. |

|

#32

|

||||

|

||||

|

what rear hubs are you using? are you using e speed hangers ? when using e speed a hangers the turnbuckle is a lot shorter and there fore changes the roll centre quite a bit mean the drive shaft will plunge more into the out drive. i am using rayspeed hubs and with the ball stud i hole a i have no trouble with drive shafts fouling the diff nut

__________________

|

|

#33

|

||||

|

||||

|

Quote:

The Atomic Carbon S2 doesn't have adjustable transmission height. It complicates matters.

__________________

|

|

#34

|

||||

|

||||

|

The X-6 also uses a shorter wishbone that the S2, so essentially the rear suspension of the X-6 and S2 are very different indeed.

I imagine the geometrics of the rear suspension are one of the componants that make the X-6 so succesfull, if one of those attributes is that the driveshafts have a large amount of plunge, then I'm happy to accept that I have to add a 3mm spacer to the shock. |

|

#35

|

||||

|

||||

|

The popping out of axels and cvds hitting the diffnut. Is this X6 issues and not x6 sqrd issues. And are the problems the same with both losi shock an AE? Never seen either one irl but thinking of changeing that. Is the axels situation solved with the sqrd kit? I mean if I can run the std axels now just fine.

A |

|

#36

|

||||

|

||||

|

Both the original car and the Squared will work just fine with the standard B4 axles & CVDs. In some cases many customers limit the shock travel on either Losi or AE shocks to assure the bones do not pop out of the outdrives.

For those who experience that problem we suggest the #5660 axles which are made for us by M.I.P. They are identical to the axles found on the Losi xxx-BK2 and fit the AE CVD perfectly. In fact they are slightly long, requiring shims on the inside of the bearing. We have found Losi #A3016 is a good length, but you can easily make up your own shims. Once shimmed correctly, most drivers report #5660 solves all problems of either hitting the diff nut or popping free of the outdrive, and allow all the droop you want. Perhaps one of the Boyz will point out any flaw in my explanation. I make the parts and sell them. They install and run 'em. The usual circle: production dept knows nothing about R & D, which knows nothing about marketing, which never talks to production. Amazing how that happens in the world's smallest R/C company... LOL |

|

#37

|

||||

|

||||

|

I just hava a question along the lines of a previous poster.

Is it intetional that the rear suspention geometry is changed compared to the B4, so that the length of the drive-shaft changes this much? After having bought an X-6, I must admit is is a bit frustrating to keep finding out all the little bits and pieces you need to supply the already purchased B4 and X6 kits.... |

|

#38

|

||||

|

||||

|

You can happily run the car straight out of the box, so to speak, and the car is very competative. In fact some people prefer the car without the axles and e speed hangers. Just because most of the "top drivers" use these parts doesn't mean that you have to have them.

Whilst the slightly different suspension geometry does increase the driveshaft plunge slightly it is the e speed hangers are the parts that give the extreme driveshaft plunge, which is partly what they were designed to do. The axles allow you to use the inner hole on the wishbone without limiting the shocks length, if you wish to do so. If you use the middle hole on the wishbone (as I do almost all the time) then you only need to add 2 or 3 internal limiters (again which I do all the time) and you can then use the B4 axles with no problems. Hope that helps a little

|

|

#39

|

||||

|

||||

|

The big thing here is that it's entirely your choice. As Craig says, the car works great right out of the box -- faster and easier to drive both at the same time.

Now, if you choose to install additional parts, we make them available so you have that choice. If one checks my results from either the Clash or Cactus, one soon realizes that I know whereof I speak when I say that, at least for me, it's not lack of the latest tuning part keeping me from the Nationals podium... |

|

#40

|

||||

|

||||

|

Ok, there is no doubt that the car is fast and easy to drive out of the box, I know that, otherwise I would not have bought it... but my point is that my car, with no e-speed hangers, std B4 axles and even a 3mm spacer inside the shock still had the axle pop out 3 times on one night, destroying 3 spurs in the process... So I do not entirely agree with you.

My point is if you/the designer intentionally designed the rear suspension to have a geometry that increases the chance of popping the axles, why not include these parts in the kit in the first place? I still have a job, so I can afford the extra cost (...) , it is more an issue of when I first can set aside an afternoon for practise, I run into a problem that I could have avoided by either reading more or less all posts in this forum, or the supplier could have supplied the right parts from the beginning... Now I ended up working on the car most of the evening instedad of driving... |

|

| Thread Tools | |

| Display Modes | |

|

|