|

||

|

|||||||||||||||

|

|

|

#1

|

||||

|

||||

|

Hi Guys,

I'm after somewhere that can make a few test parts that I have designed out of aluminium. They are not that big. Any ideas? Ta

__________________

http://www.thercracer.com/ |

|

#2

|

||||

|

||||

|

I might be able to help, I work in engineering, depends what they are and how much detail is in them.

Most of my stuff for rc is done as a "govie job" Send me details of what it is and ill see what can be done. |

|

#3

|

||||

|

||||

|

The milling itself is usually quite quick and hopefully painless.

It's the hours of programming and working out how the hell you are going to hold it that is the issue! Not to mention manufacturing complicated fixtures to make one-offs!  If all else fails then give me a shout but I'm not actually a charity. But nearly!

__________________

Clive Check out the goings on at HBI here: https://www.facebook.com/pages/Heske...68872353145927

|

|

#4

|

||||

|

||||

|

Size is pretty much irrelevant, assuming they are RC parts they are never going to be huge. What Clive said above is very much relevant though. Post pics/drawings.

|

|

#5

|

||||

|

||||

|

Sorry for the late reply, I had to go abroad for work.

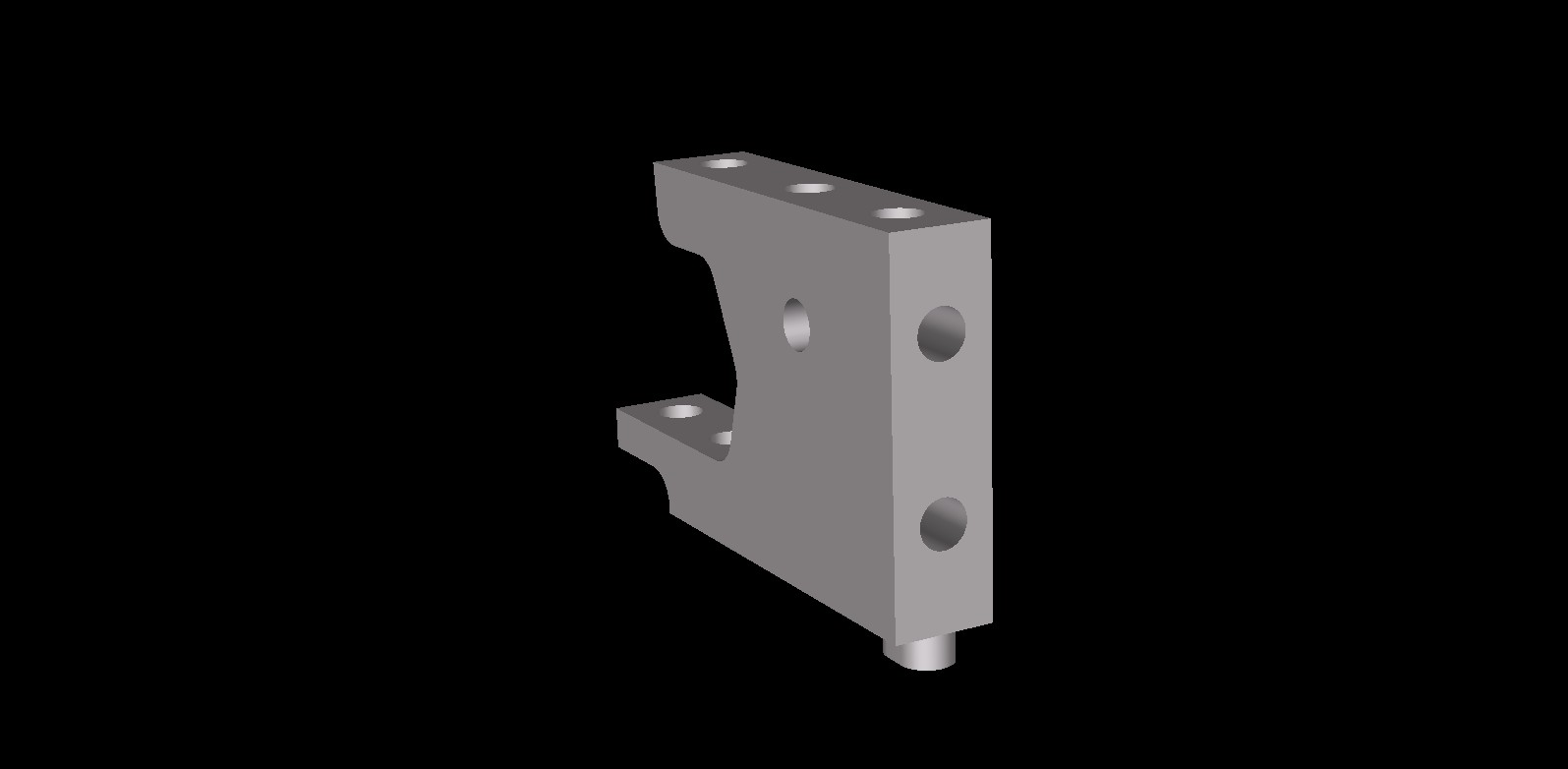

Anyway, it is an inner servo mount. 6mm thick. 23mm high and 33mm long Here is a 3D image of it from the Cad package

__________________

http://www.thercracer.com/ Last edited by qatmix; 25-03-2016 at 05:05 PM. |

|

#6

|

||||

|

||||

|

Looks like it needs machining from five sides.

Front and back can be done from the plate material, making it easy to hold. The drillings from the other three faces will require at least two fixtures to be made to present the job in the right attitude. It ain't five minutes. PS Another hole on the front face might help, so that it can be used as a tooling hole to align the workpiece on the fixtures.

__________________

Clive Check out the goings on at HBI here: https://www.facebook.com/pages/Heske...68872353145927

Last edited by Clive Loynes; 11-04-2016 at 10:54 AM. |

|

| Thread Tools | |

| Display Modes | |

|

|