|

||

|

|||||||||||||||

|

#1

|

||||

|

||||

|

Just got myself an X6 to have a go at 2WD as I normally run 4WD, hence I have only saddle Lipo's.

I've heard that quite a few people run saddles in the X6, by doing a few mods. Can anyone let me know what mods are needed, and if possible post some pics? Many Thanks |

|

#2

|

|||

|

|||

|

Longer connecting lead and just put them in one behind the other. Thats all I do anyway.

Or you can buy the lipo chassis, or cut yours up. |

|

#3

|

||||

|

||||

|

If you mount like a stick just be a bit carefull with the terminals and the carbon battery brace (which conducts). Most people I've seen do this dremel the strap to get extra clearance for the connectors just in case.

Dremelling the chassis to fit in the middle requires some skill and a good cutting bit (not sanding drum), OK if you got the skills and equipment but much easier to buy the saddle chassis.

__________________

Nortech is ACE! |

|

#4

|

||||

|

||||

|

Ah right, I didn't realise you could buy the chassis ready for saddles, sounds like this is the way to go, cheers guys.

Quote:

|

|

#5

|

|||

|

|||

|

Part number is XF1009...

__________________

ORCA - LC RACING - RUDDOG PRODUCTS - JCONCEPTS - ALPHA PLUS - TEKIN RACING - ULTRAPOWER AVID R/C - VAMPIRE RACING - EXOTEK RACING - LUNSFORD RACING - X-FACTORY - TUNING HAUS - WTF AME - RAGE R/C - REVOLUTION DESIGN RACING PRODUCTS - McKUNE DESIGN - TEAM AZARASHI X-PARTZ - PHAT BODIES - RACERS EDGE - RM2 - DIRT RACING PRODUCTS - DMS INSERTZ TKR GRAPHICS - BF MATERIALS - BATAN - DMS PARTZ - TEAM AJ Tel : (01923) 816636

|

|

#6

|

||||

|

||||

|

You could always fit saddles end to end in a stick shape and drop them in across the width of the chassis as is. You wouldn't need any mods at all to fit them into the standard chassis then....just as dan suggested above...

The saddle mod arranges them side by side in the centre of the car instead, leaving less space for electrics at the front, but getting the battery weight more central. Yet another tuning aid in the already huge array of tuning options!!!

__________________

AKA: Andy Nancollis 1/10th drives: Yokomo BMax2MR & BMax4 1/16th drive: Carisma GTB Racing in South West: http://www.mendiprcraceway.co.uk/ Racing in Wales: www.caldicotrcracers.co.uk Kept running by: Yokomo via MB Models & www.tracksidespares.co.uk Shells by Square Crabs |

|

#7

|

||||

|

||||

|

A big new load of #1009 saddle chassies shipped to X Factory UK last week. Should arrive late this week.

|

|

#8

|

||||

|

||||

|

Can someone who has the saddle chassis take accurate dimensions of the mods that are made to take the saddle packs? I have access to a milling machine so should be a 5 min job to do it.

|

|

#9

|

||||

|

||||

|

can some one post soem pics of where the speedo now sits in there car with this chassis

__________________

Team Associated- HobbyWing- Reedy- CML |

|

#10

|

||||

|

||||

|

Same place...just a bit further forward!

It's a pretty close fit behind the servo, but still ok

__________________

AKA: Andy Nancollis 1/10th drives: Yokomo BMax2MR & BMax4 1/16th drive: Carisma GTB Racing in South West: http://www.mendiprcraceway.co.uk/ Racing in Wales: www.caldicotrcracers.co.uk Kept running by: Yokomo via MB Models & www.tracksidespares.co.uk Shells by Square Crabs |

|

#11

|

||||

|

||||

|

muchos for the fast reply

__________________

Team Associated- HobbyWing- Reedy- CML |

|

#12

|

||||

|

||||

|

Mark, I would take a saddle and machine to fit so you can get it nice and tight. You also might want to consider the side little ribs which I've removed in part to aid fitting the large (ish) futaba receiver I use. I've done both side to even the flex which has meant fitting electronics easy. To note though I've only lowered to the height of the lead plate I used under the speedo 100% of the time, no need to totally remove them.

__________________

Nortech is ACE! |

|

#13

|

||||

|

||||

|

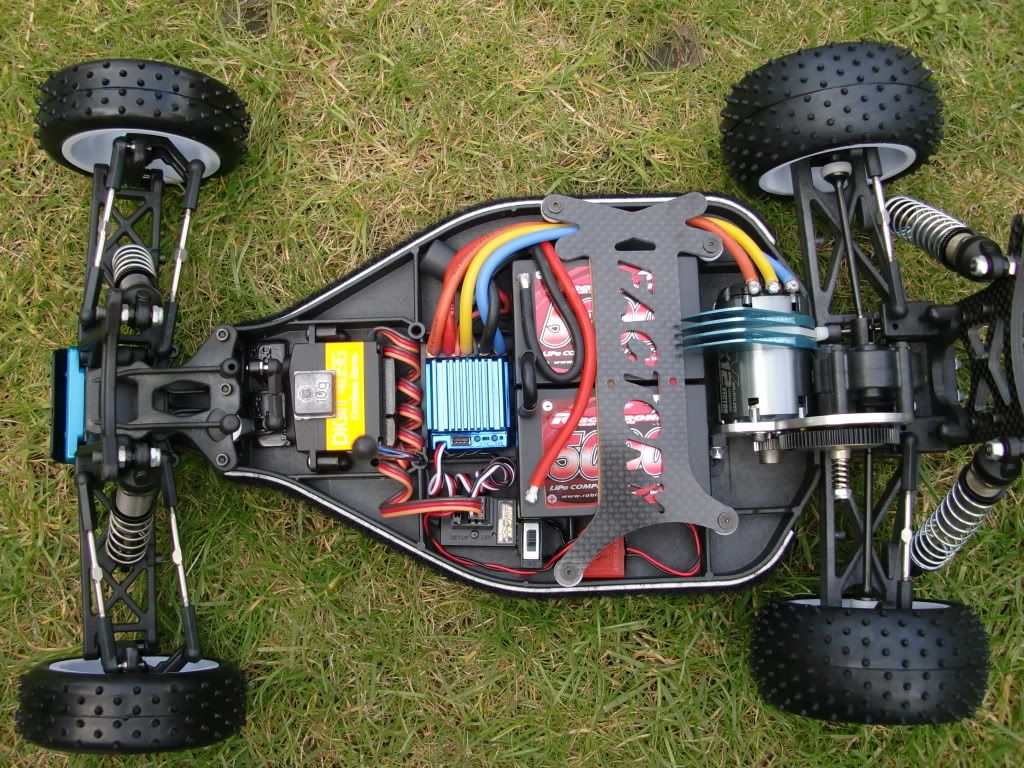

Pic of mine for you

|

|

#14

|

||||

|

||||

|

That's a nice clean build.

|

|

#15

|

|||

|

|||

|

Here's mine below - very similar layout to that of John Kirkham's earlier in the thread. (must be the Southport air!!!)

Having the saddle arrangement raises a question in my mind - why not produce a new narrower chassis with at least 40 mm shaved off the width? That would still leave plenty of room for all the gear. I'm guessing that this would give the X6 even more stability with the weight even closer to the centre line. I'd certainly be willing to buy one. Over to you Chazz.

__________________

Tony Mulligan DESC410R, DEX410, DEX210, Cream Extreme (the dog's b******s) www.srcc.co.uk |

|

#16

|

||||

|

||||

|

Would require an entire new chasssis mold, Tony. You don't want to hear about the cost...

|

|

#17

|

|||

|

|||

|

Chazz

I have always wondered what are the true costs of a mold? I heard many years back that the mold for an offroad wheel was more than $10,000 but I didn't know how accurate that information was at the time. I can appreciate that the mold for an offroad chassis is more complex than a wheel and would make the mold more costly. Is my information in the 'ballpark'? I'm just curious. |

|

#18

|

||||

|

||||

|

It's got the right number of zero's, but the first digit is not high enough for a chassis!!!

Tooling is mega bucks...think many many hours (as in many weeks worth) of machining time to create a solid lump of steel/aluminium that is split into at least 2 parts, closes together absolutely perfectly across ALL the joining faces, cooling channels, feed channel, venting, ejection system (to automatically push the plastic part out). Then there's the bolster blocks that sit around it, again cooling, ejection, feed, and all the features the bolster needs to sit it into the moulding machine. The tool is a big rectangular metal lump and complex mechanism that ends up being 3-4 times the size of the part it's making! All that time, detail and raw material adds up big time!!! The end result is a tool that can mould you tens to hundreds of thousands if parts that cost pennies there after though...think big consumer product manufacturing here...it's the same technology!! And after that do the maths on how much an entire RC cars worth of plastic parts costs to tool in the first place! ;-)

__________________

AKA: Andy Nancollis 1/10th drives: Yokomo BMax2MR & BMax4 1/16th drive: Carisma GTB Racing in South West: http://www.mendiprcraceway.co.uk/ Racing in Wales: www.caldicotrcracers.co.uk Kept running by: Yokomo via MB Models & www.tracksidespares.co.uk Shells by Square Crabs |

|

#19

|

||||

|

||||

|

here's my cuban cigar saddled up

__________________

Custom MG-Racing Associated DMS |

|

#20

|

||||

|

||||

|

I'm thinking about milling my squared chassis to the saddle pack modification. Having a look at the pics on this page i was thinking about milling the chassis right up to the brace behind the servo. The idea being that you can move the saddles more towards the front of the car to give you more tuning options. I suppose doing this you could only mount the ESC near the motor.It's just an idea at the mo so would like to hear feedback on wether this might be a good idea. ( or a crap one like mine normally are

). ).

__________________

Jolly Goodz. WBMCC. Team Autocare and Cycles. |

|

| Thread Tools | |

| Display Modes | |

|

|