|

||

|

|||||||||||||||

|

#1

|

||||

|

||||

|

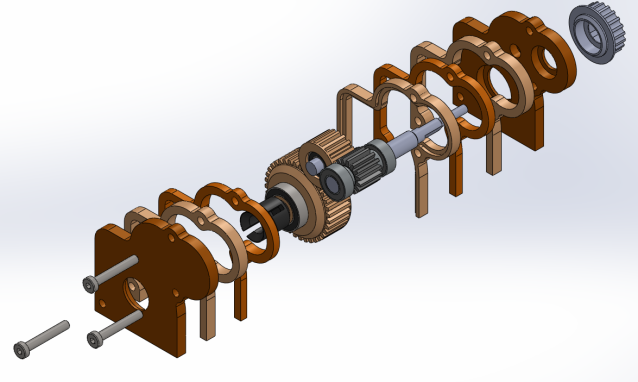

This is the result of the first few hours of design work on a gear/belt 4x4

The idea comes from a mate, CNC cutting wil be done by an RC brainiac who build his own CNC cutting mill All gears are from the Associated SC 4x4 (very sturdy stuff and METRIC) All gearbox parts are made of epoxy plate, partially laminated together, partially screwed together . Next step is to show the design to our CNC-guy to find out if the idea is at all feasible    Grtz Steven |

|

#2

|

||||

|

||||

|

If this is going to be made by the same person who made the very interesting 2wd mid motor I saw last week, this is definately very promising!

|

|

#3

|

||||

|

||||

|

the exicuting force on this car will be the same as the 2wd only the desining team is a bit bigger . but it will defenetly be good lol.

__________________

topspeed modelshop Ralls racing Rc-speedhouse Rude-Bits Serpent Fba section offroad chairman. |

|

#4

|

||||

|

||||

|

Tamiya did one and was very promising, Alan Harman and Ellis Stafford used it in the 90s and was consitantly making the A's, however Kyosho did one of these as well and wasnt very promising, hence why it was dropped, however for a design point of view its a good one to do.

A couple of guys on the RC10 Forum have already done this and converted a B2 and a B4 to 4wd using belt on the front axles, and pretty similar to your design.

__________________

www.kamtec.co.uk www.fibre-lyte.co.uk answer-rc.com/uk/en/ Answer UK team driver Designer of the Lazer ZX/ZXR carbon fibre tub chassis Designer of the Lazer ZXRS |

|

#5

|

||||

|

||||

|

Just like the drive system on the old mip rc10's exept belt not chain. Like the simple gearbox construction though

|

|

#6

|

||||

|

||||

|

that the idee issent new wel all would now that . as its almost all been done .

and getting a new angle or somthing comleet new is 1 chance in a million . the same is like with the base of car we are starting from . as I have run the most out there the choise was hard . and in this proces we are working aswell on the new drive train for the car aswell as on getting glitches out of the geometrie of the car . we still have a long way to go but we are getting there .

__________________

topspeed modelshop Ralls racing Rc-speedhouse Rude-Bits Serpent Fba section offroad chairman. |

|

#7

|

||||

|

||||

|

you could do away with idler gears as well if your belt pulleys are small enough and you use a seperate slipper/spur assembly, or even use diferent numbers of idlers to change the effect of the rotating mass of the spur gear afects the car, could make it a very interesting project

|

|

#8

|

||||

|

||||

|

Isn't this the same principle as the X-7??

__________________

dragon paints : team tekin : fusion hobbies :SCHUMACHER RACING : Nuclear R/C for all my sticky and slippery stuff - if it needs gluing or lubing, Nuclear RC is the man! |

|

#9

|

||||

|

||||

|

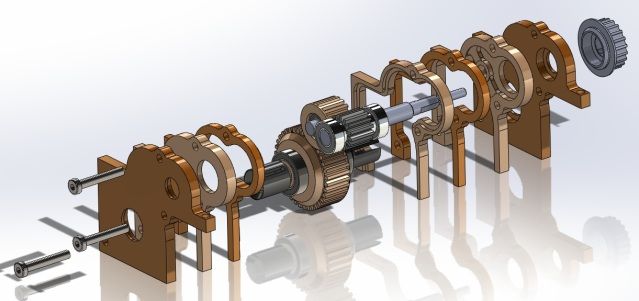

We only used the idlers to get some extra height to get over the battery-pack (shorty cross-wise)

As far as trying to get motor-rotation "right", we decided not to further complicate things and just see how the rotation comes out. @DCM : who knows  never seen lid-off shots of an X-7 never seen lid-off shots of an X-7In the meanwhile I've updated the design with some tabs for a topdeck and done some work to space out the gears inside :

|

|

#10

|

||||

|

||||

|

With the casing made from 7 components how will you control lateral tolerance stack up? Will you need to shim the gears?

|

|

#11

|

||||

|

||||

|

All joints between layers will be glued, exept for the center joint, where the two layers will key together .

For the first prototype, I've allowed for some lateral tolerance for the gears and axles, so some slight shimming will be necessary |

|

#12

|

|||

|

|||

|

|

|

#13

|

|||

|

|||

|

Not sure if I'm missing something, But why have you made it out of several layers? why not just two, i.e. left side and right side?

|

|

#14

|

||||

|

||||

|

Are you getting layera water jet cut in stead of milled.

manic

__________________

pro95 (s/n111554), dtmi, rally, xk98 (in the post), XRS (s/n6120), X10, X11-08, X11 lipo B4.1 vega |

|

#15

|

||||

|

||||

|

Good to know we"re not copy'ing the X-7 then

Good point cream; we're using an home-made (not by me) cnc milling machine, it's proven itself "worthy" cutting 4 mm epoxy; but I think if we go with thicker material, we'll be in trouble ... |

|

#16

|

|||

|

|||

|

Quote:

Then just cut it in 4mm cuts. Your making a lot of work that's not needed and weakening your overall finish item. |

|

#17

|

||||

|

||||

|

Mip did a belt version as well, worked better than the chain

__________________

www.kamtec.co.uk www.fibre-lyte.co.uk answer-rc.com/uk/en/ Answer UK team driver Designer of the Lazer ZX/ZXR carbon fibre tub chassis Designer of the Lazer ZXRS |

|

#18

|

|||

|

|||

|

RC-Trix, nice little project.

Have you seen the Tamiya TA-06 - it uses the same design as this, it might give you some further ideas. |

|

#19

|

||||

|

||||

|

Nice but old design, my Tamiya TRF 411x had that already in the previeus century ;-)

Regards, Bart |

|

| Thread Tools | |

| Display Modes | |

|

|