The winter break has given me an opportunity to get some pretty substantial progress made. I also received the parts I need for the rest of the build.

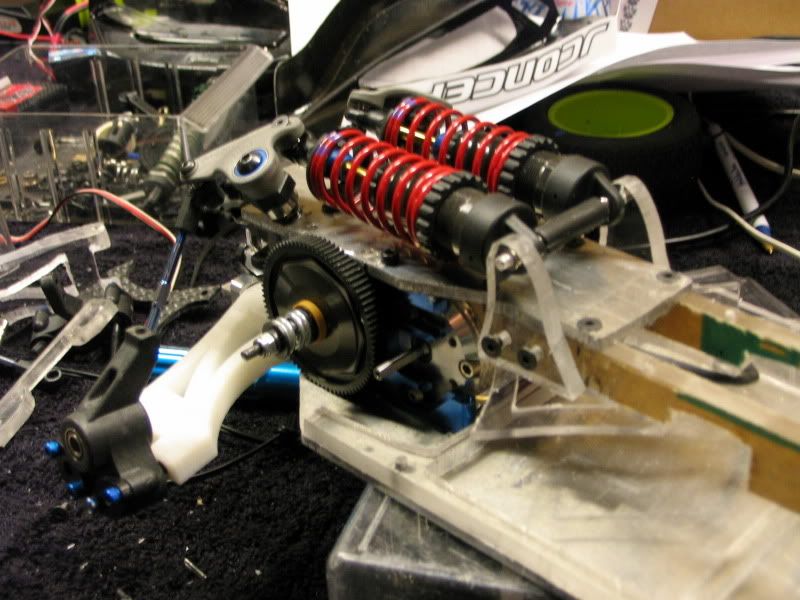

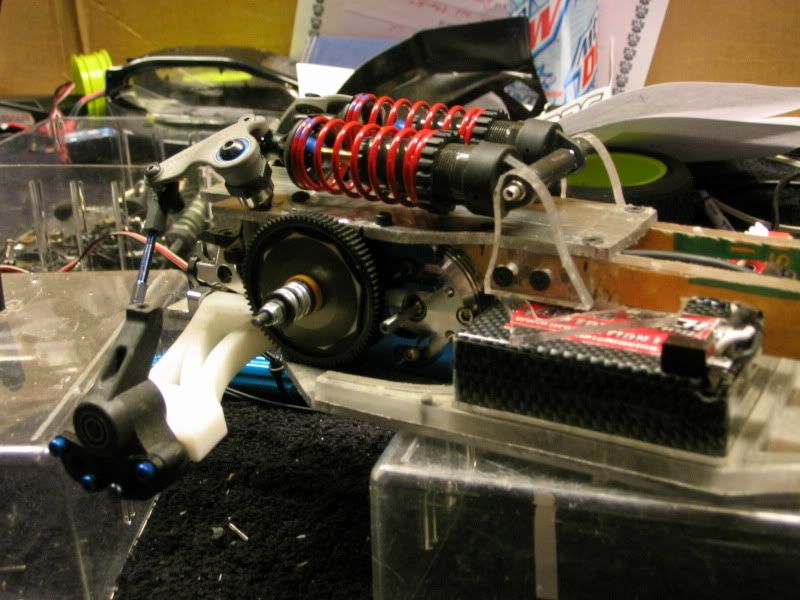

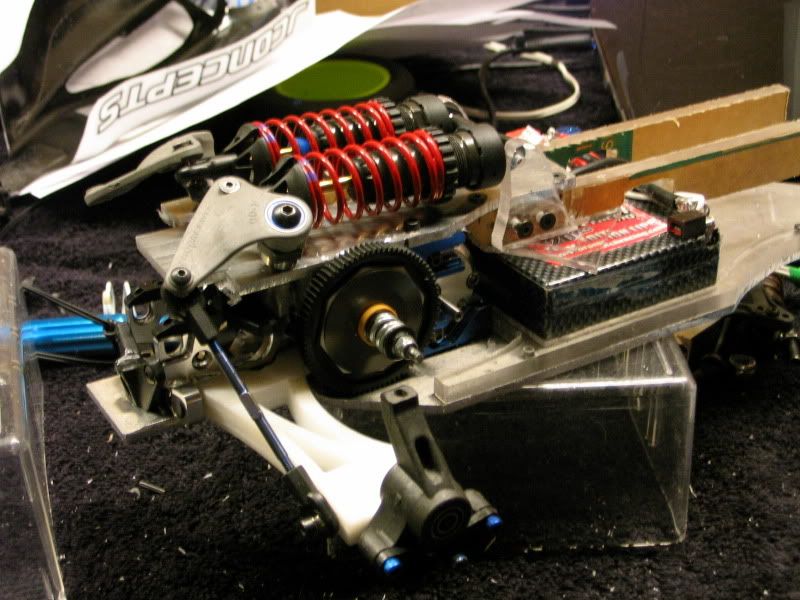

I started by building and installing the E4 diff. This required me to cut a hole under the diff so it can sit fully. While I was at it fully mounted the motor mount and filed the motor slot in the chassis. I currently don't have the diff in the buggy so that I can test the suspension (The a-arm doesn't work with the diff atm)

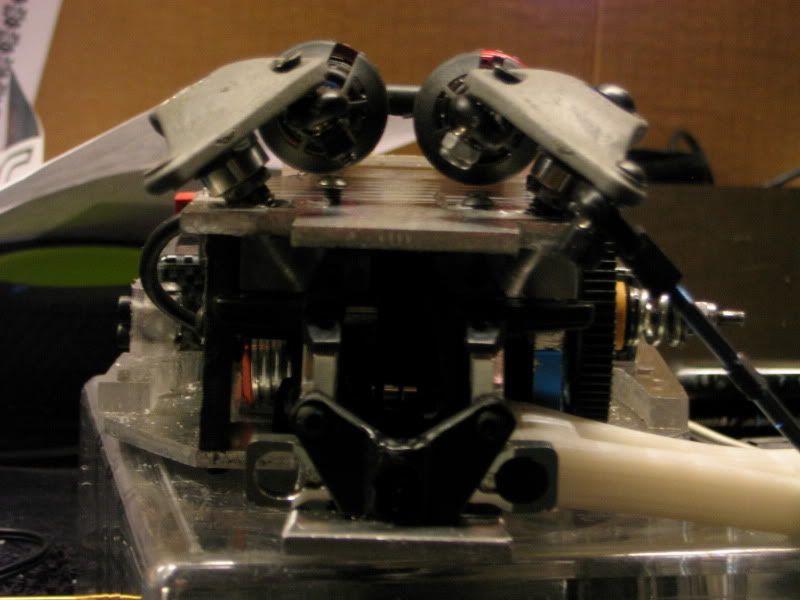

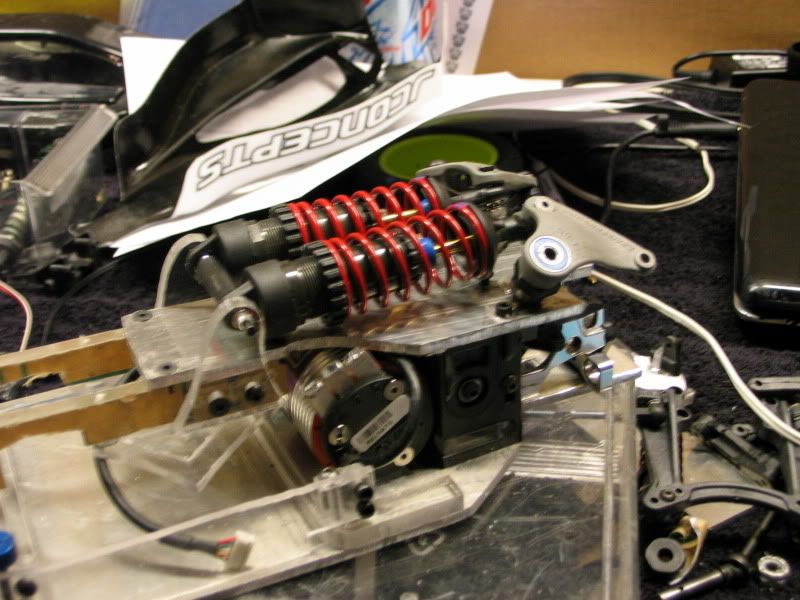

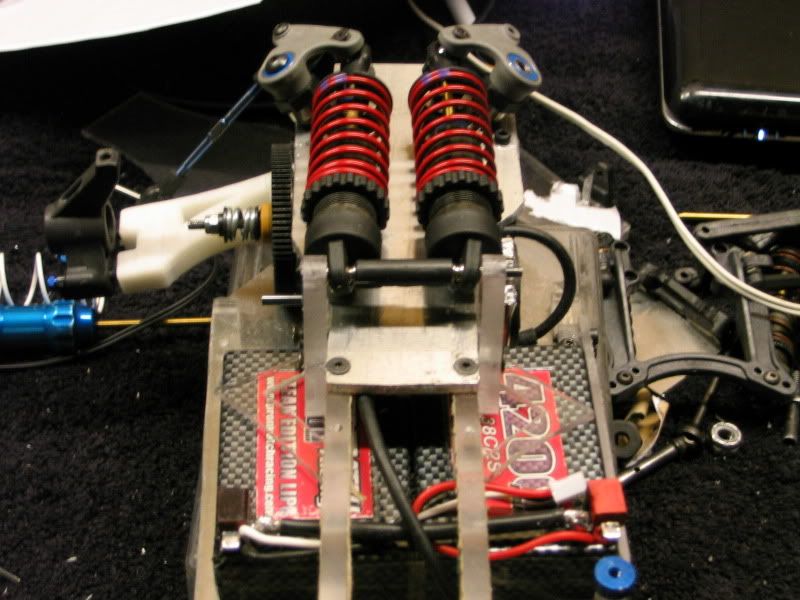

After I got the diff installed and started working on trying to figure out a way to mount the rocker posts for the laydown suspension. I decided on making a custom mount out of 3/8" lexan. With my drill press this was a much easier task then it has been in the past with my hand drill. I measured the angle of the rocker posts on my Evo8 project (Slayer buggy) and matched it. I had to cut a channel in the center of the mount for the belt to go thru.

After I got that all mounted up I moved on to cutting the upper chassis out of 1/8" aluminum. At this point I took a break and decided to do some electrical work so that I could make the center upper chassis.

My Promatch Saddle battery packs don't have built in bullet connectors but I like how clean bullet connectors are. So I came up with a solution using Dean connections. I will let a picture speak for this modification.

I also used packaging tape to tape the saddles together to make it easier to slide the battery in the buggy.

After I cut the battery done I was able to cut the center part of the upper deck out of 1/4" lexan. I had to cut slots out of the lexan for the deans to pass thru as the battery slides into place. I then got the shocks mounts made and mounted them. I made it so I can easily adjust the shocks forward and backwards.

Anyway... the pictures explain everything much more clearly. I haven't been able to take all the paper off of the Lexan becuase I still need to cut down the center upper chassis. I think it will look good once all the paper is off.

Remember all the aluminum plate parts will be replaced with Carbon down the road.

On to the pics...

Oh and a quick picture of the workshop in its current state haha.