Thanks Jonmack

Even though I was supposed to be studying for a math test today I decided to dedicate sometime to the project.

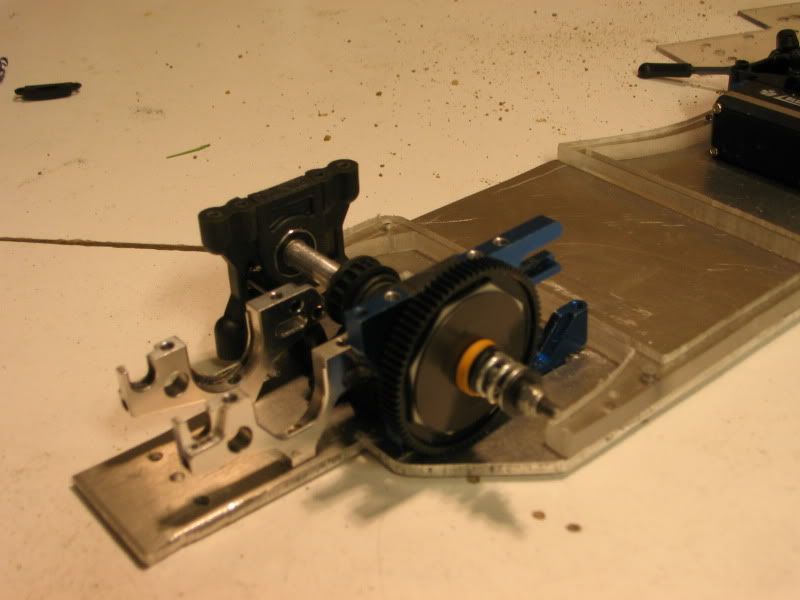

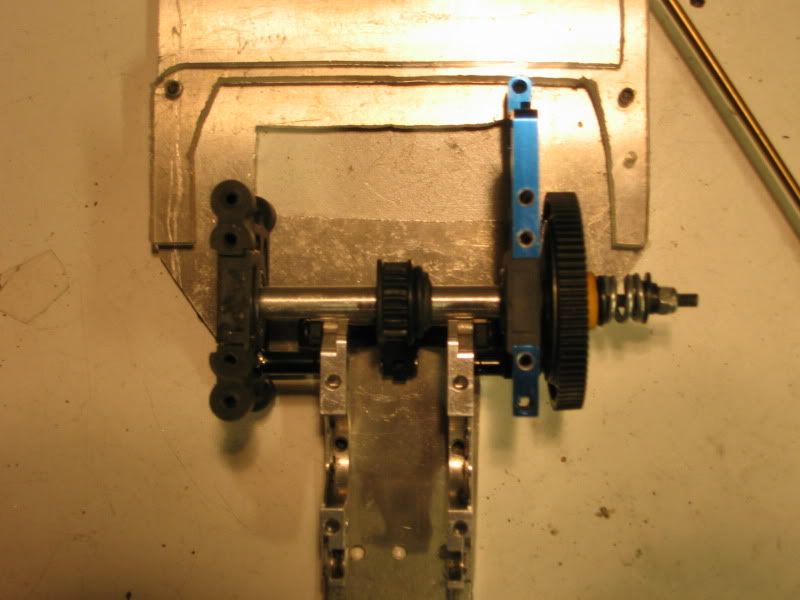

I knew when I started this project that I would have to find some way to put a slipper clutch on this since their is no factory slipper clutch for the E4.. though why would their its an on-road car. Since this is an off-road car it has to have a slipper clutch.

After looking at different factory slipper clutches I realized I would have to design and build my own. I attempted to make one a couple months ago out of a cut up tc3 aluminum center drive shaft. Everything was going good until I had to thread the threaded rod into the aluminum piece. I used a drill to thread the threaded rod in the aluminum but soon realized the hole was too small. The threaded rod ended up breaking off in the aluminum shaft and the hours of filing went to waste

Today I successfully made a slipper clutch out of a aluminum rod I picked up at Home Depot. I spent a few hours "latheing" it down in certain spots by throwing it into the drill press and using a file. I also had to file flat spots in it so the B4 slipper plates would fit.

Overall it came out awesome and this has to be one of the nicest pieces I have ever made. Now I won't have to worry about this project coming to dead end becuase their is no slipper clutch.

(I still have to file the motor hole in the chassis)