Change of plans..

I will be cutting the chassis out of 3mm aluminum first becuase of my uncertainty with the amount of traction this mid-motor layout will provide. I don't want to cut a chassis out of carbon then find out I have to redesign it and make another chassis. I will be continuing with the planned layout for now.. I will test it and if it doesn't have enough traction I will try moving half of the saddle pack behind the diff in a custom protective case. During the testing I will be comparing the car to my B4 buggy. If the layout of the B4 seems to be performing better I will go back to a traditional layout with a rear-motor but will still have a laydown suspension, strong a-arms, and hubs, 12mm hexs, etc. Once I'm sure that a certain layout will work then I will end up cutting the chassis out of the carbon fiber

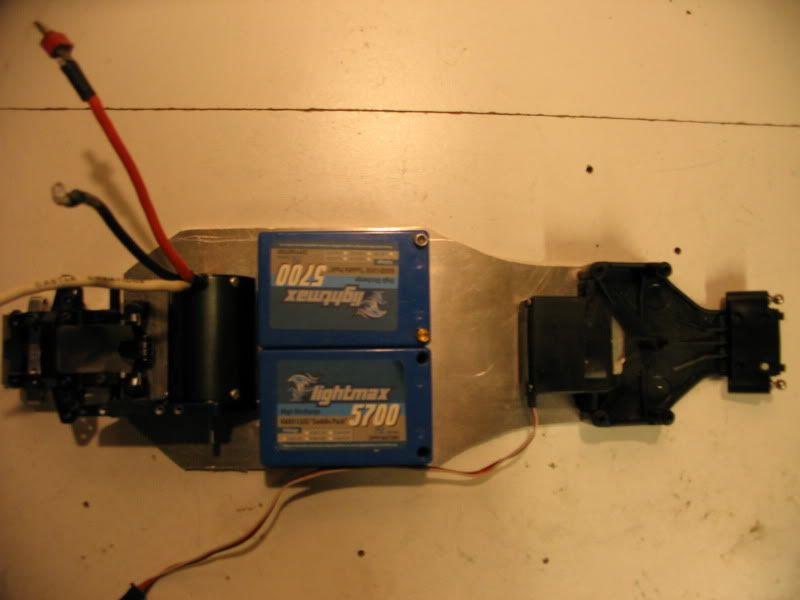

I was able to cut and drill the chassis yesterday. I think it turned out pretty good. With some more filing I think it will work nicely for testing.

I have been hurrying to get my design for the a-arms finalized so that I can 3d print them at school before Christmas break. I am pretty close.. have a few small changes but this is what they will look like. When they are 3d printed the parts that are thick will actually be skinnier then they look. I had to make them pretty thick in area's becuase ABS plastic isn't the strongest stuff. I might eventually look at getting them milled out of delrin. But I'm hoping these will hold up.